Comtech Machinery Co., Ltd. is dedicated to providing exceptionally durable and stable ribbon weaving machines for narrow fabric weaving factories. The ribbon machine structure is not complicated, and allows for a long term, stable performance as long as all components work perfectly together as a full system. We are proud of our advanced processing technology for all loom parts, allowing us to provide our customers with the most qualified and trustworthy equipment.

- Materials

The narrow fabric weaving loom body and parts are all chosen based on customer requirements. Traditionally, we use G65 bearing steel, 45# steel, or manganese steel to ensure the intensity and running stability.

After the raw materials are put in storage, they will remain in storage for 6 months of natural aging prior to rough machining and heat treatment.

- Processing

Raw materials are first cut using the optical laser cutter, then undergo a heat treatment such as quenching and tempering in order to improve the strength and ductility.

The machine body is using a large argon shield welder that creates a sealed welding line without air holes or sand holes. This method is more environment friendly, as it avoids creation of any toxic gas that harms operator health.

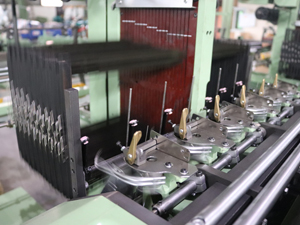

Fine processes are carried out by CNC equipment. Comtech has more than 40 vertical and horizontal CNC centers in order to precisely control machine body and computerized loom parts.

- Quality control

Before being put in the storage, all materials will be examined or tested to ensure they meet quality standards.

Before assembly, the second sifting will be conducted, and any unqualified parts will be removed to ensure each component to the weaving machine is 100% qualified.

After assembly, we maintain the loom in an idle mode for a continuous 120 hours at the highest speed to ensure equipment operates correctly. If even the smallest part appears to have a problem, we will not use it, and will be found in advance. Every ribbon weaving machine sent to our customers is qualified and reliable, leading to higher production benefits.

- Cost control

Our factory is located in Zhejiang, giving us access to sufficient and extensive industrial resources. All raw materials we need are located within a 5kM circle, which significantly reduces transportation costs.

All parts and components are processed in house, leading to lower purchasing costs.

We have been dedicated to the production of woven tape machines for a number of years, and our expertly trained employees help us reach an annual output of more than 4,000 pieces of equipment. Such a large scale production decreases average production costs.

- Jacquard Loom

- KTNFM53-4/66-768 Jacquard Loom

- KTNFM53-6/50-384 Jacquard Loom

- KTNFM53-4/66-192 Jacquard Loom

- KTNF53-4/66-320 Jacquard Loom

- KTNF53-6/42-384 Jacquard Loom

- KTNFS53-2/175-1152 Jacquard Loom

- Tape Festooning Machine

- Needle Loom

- KTNFB78-2/130 Narrow Fabric Needle Loom

- KTNFB53-8/27-20 Needle Loom

- KTNFB53-6/42-20 Needle Loom

- KTNFB78-12/27-16 Needle Loom

- Intelligent Warp Tension Control Warping Creel

- Passive Warp Tension Control Warping Creel

- Active Warp Tension Control Warping Creel

- Integrated Active Warp Tension Control Warping Creel